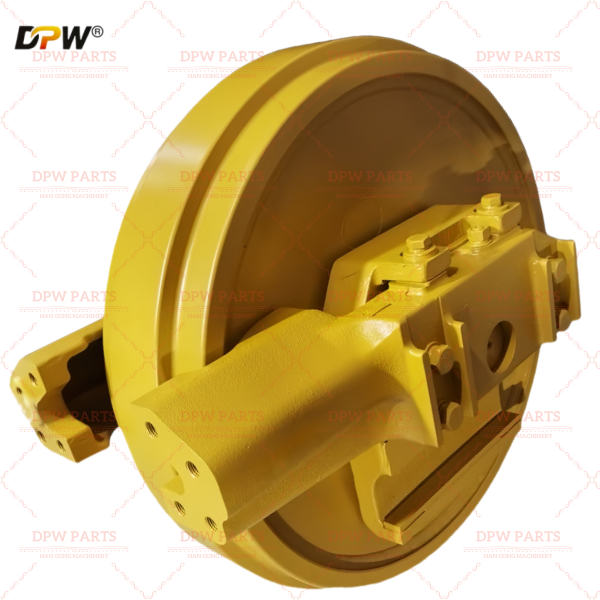

KOMATSU UX106K1E / 154-30-00770 /1543000771/ D85EX-21 Forged Track Idler Wheel Assembly/Heavy duty Track Bulldozer Forged Idler Manufacturer-HAN GONG /DPW PARTS

Product Specifications

Introduction: The Critical Role of the Track Idler in Bulldozer Undercarriage Systems

The undercarriage of a heavy-duty bulldozer like the KOMATSU D85EX-21 is a rigorously engineered system designed to support immense static and dynamic loads while providing stability and traction. The Track Idler Wheel Assembly, located at the front of the track frame, serves multiple vital functions: it guides the track chain smoothly, maintains proper track tension and alignment, and absorbs substantial forward impact shocks during dozing and grading operations. Unlike rollers, the idler must withstand significant lateral forces and shock loads from track slap and terrain impacts. The Forged Track Idler, represented by part numbers UX106K1E, 154-30-00770, and 1543000771, is engineered specifically to meet these extreme demands with superior strength and durability.

Technical Analysis: KOMATSU D85EX-21 Forged Track Idler Wheel Assembly

This assembly is a precision component whose design directly influences track life, machine stability, and final drive protection.

Primary Functions & Operational Stress:

Track Guidance & Alignment: The idler's precisely machined flange guides the track chain, preventing lateral derailment.

Impact Absorption: It acts as the first point of contact for track chain shock loads, transferring these forces into the track frame and recoil mechanism.

Tension Management: As the pivotal point for track adjustment, the idler's bearing and housing integrity are crucial for maintaining optimal track tension.

Forged Construction vs. Traditional Casting:

The designation "Forged" is central to this component's performance. HAN GONG/DPW PARTS manufactures this idler using a closed-die forging process.Metallurgical Superiority: Forging refines the grain structure of high-grade alloy steel (such as 40Cr or similar), aligning the grain flow with the idler's contour. This results in a continuous, unbroken grain pattern, dramatically increasing impact toughness, fatigue strength, and tensile strength compared to cast idlers, which can have porous, inhomogeneous structures.

Density and Integrity: The forging process compacts the metal, eliminating internal cavities and gas pockets, leading to a denser, more reliable component capable of handling the high-cycle fatigue of heavy dozing.

Component Breakdown & Engineering Details:

Forged Idler Body/Rim: The core forged piece is machined to exact OEM dimensions. The running surface is hardened through induction quenching to achieve a deep, uniform hardness (typically 55-60 HRC) for exceptional wear resistance against the track chain link.

Integrated Flange: The guidance flange is an integral part of the forged body, ensuring maximum strength to resist bending and breaking under lateral stress.

Bearing Hub & Sealing System: The assembly incorporates a robust hub designed to house large-diameter tapered roller bearings. This bearing system is selected for its high radial and axial load capacity. Critical to longevity is the multi-stage sealing system—often featuring a combination of radial lip seals and labyrinth grease cavities—that aggressively excludes abrasive contaminants (mud, sand, dust) from the bearing compartment.

Lubrication Fittings: Provision for standard grease zerks allows for routine purging and lubrication to extend seal and bearing life.

Manufacturer Profile: HAN GONG / DPW PARTS - Specialists in Forged Undercarriage Components

HAN GONG, operating under the brand DPW PARTS, is a focused manufacturer with expertise in producing high-wear undercarriage parts, with a pronounced specialization in forged components for heavy-track applications.

Advanced Manufacturing and Quality Protocol:

Forging-Centric Production: Their core competency lies in in-house die design, heating, forging, and controlled cooling processes. This ensures direct control over the material's mechanical properties from the very first production stage.

Post-Forging Thermal Treatment: Following forging, components undergo normalizing or quenching and tempering (Q&T) to relieve internal stresses and achieve the optimal balance of hardness and toughness throughout the material matrix.

Precision Finishing: State-of-the-art CNC lathes and grinding machines finish the forged blanks to exact OEM blueprints, guaranteeing perfect dimensional conformity for the KOMATSU D85EX-21.

Comprehensive Quality Assurance: The production chain is supported by ultrasonic testing to detect any subsurface flaws in the forging, hardness testing across all critical wear surfaces, and dimensional verification using precision gauges and CMM technology.

Value and Application Philosophy:

DPW PARTS positions its Forged Track Idler Assemblies as performance-enhancing solutions. For models like the D85EX-21, this translates to:

Extended Service Intervals: The combination of forged strength and superior sealing reduces downtime for undercarriage maintenance.

Reduced Total Operating Cost: Longer idler life protects adjacent components (track chain, rollers) from abnormal wear, lowering cost-per-hour metrics.

Direct OEM Interchangeability: Manufactured to original Komatsu specifications (UX106K1E), ensuring seamless installation and operation.

Reliability in Severe Applications: Particularly suited for high-impact, high-abrasion environments where cast components may be prone to catastrophic failure.

Maintenance and Replacement Best Practices

Regular Inspection: Monitor for excessive flange wear, groove formation on the running surface, and any signs of bearing seal failure (grease leakage or contamination ingress).

Proper Tensioning: Always maintain track tension according to the operator's manual to prevent undue stress on the idler bearings and track components.

Systematic Replacement: Consider the wear relationship between the idler, track rollers, and the track chain itself. Replacing severely worn components in isolation can accelerate wear on new parts.

Conclusion

The KOMATSU UX106K1E (154-30-00770/71) Forged Track Idler Wheel Assembly is a fundamental component for the durability and efficiency of the D85EX-21 bulldozer's undercarriage. Opting for a forged idler represents an investment in mitigating the risks of impact fracture and premature wear. HAN GONG (DPW PARTS), through its dedicated focus on forging technology and precision manufacturing, establishes itself as a credible source for these critical wear parts. Their product offers equipment managers a robust, OEM-compatible alternative that prioritizes mechanical integrity and lifecycle value for the most demanding bulldozing and earthmoving applications.